Carbide round bar, tungsten round bar, round bar custom, round bar production

- group name

- Tungsten Carbide Rods

- Min Order

- 1 piece

- brand name

- TDC

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, PayPal

- update time

- Fri, 21 Sep 2018 09:39:18 GMT

Paramtents

Name Carbide round bar

Material Tungsten carbide

Type Wear parts

Origin Hunan,China

Density 16.4g/cm

Hardness HRA89-92

Surface Uncoated

Customized Accept

Grade YG8 YN8 YG6X...

Certificate ISO9001

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

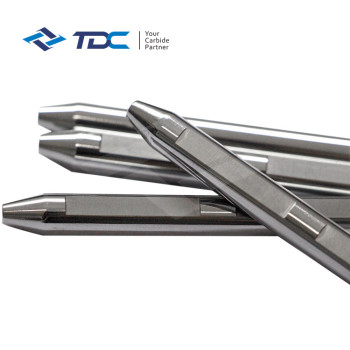

Tungsten steel rod Product Details:

Tungsten steel round bar is a tungsten carbide tungsten carbide (WC) as the main raw material, together with cobalt powder, paste phase by powder metallurgy method pressed sintering

High hardness, high strength alloy bar.

Recommended grades: YG6 YG8 YG6X YG10X YG15 YL10.2 YS2T, etc., according to customer requirements.

Product Size: Diameter 0.45-40mm, total length 1-400mm, can also be produced according to customer requirements.

Product Type: Solid round bar, single hole round bar, double round bar, spiral round bar, rough and fine grinding can produce.

Product parameters

Grade | hardness | density | Flexural strength | standard |

YG6 | 90.5-91.5 | 14.8-18.0 | ≥2150 | K10-K20 |

YG8 | ≥89.5 | 14.6-14.8 | ≥2320 | K20-K30 |

YG6X | 91.5-95.5 | 14.8-15.0 | ≥1560 | K10 |

YG15C | 85.0-86.0 | 13.9-14.1 | ≥2400 | K40 |